Related Products

Annealing Lehr, designed for the continuous annealing process of glass containers, jars, glassware, and similar products,

It is used to eliminate internal stress in glass products due to rapid cooling during the molding process.

Gas-fired BLTHL-YQ(X) series and electric heating BLTHL-D(X) series hot air circulation annealing furnace are suitable for annealing treatment of continuous production of glass bottles, utensils and other products

Annealing Lehr, designed for the continuous annealing process of glass containers, jars, glassware, and similar products

The lehr features an all-steel structure and is assembled in sections for ease of transportation, enabling rapid on-site installation. The mesh belt width typically ranges from 600mm to 5000mm.

Annealing Lehr, designed for the continuous annealing process of glass containers, jars, glassware, and similar products, is used to eliminate internal stresses generated during the forming process due to rapid cooling

The lehr features an all-steel structure and is assembled in sections for ease of transportation, enabling rapid on-site installation. The mesh belt width typically ranges from 600mm to 5000mm.

The BLKHL(X) series forced hot air circulation decorating lehr is designed for continuous secondary processing of glass bottles, containers, and similar products, including spray coloring and decal application.

In addition to firing glass products with silk-screen printing, spray coating or hand-applied decals, the BLKHL(X) series hot air circulation decoration furnace can also complete an annealing process to avoid internal forces caused

The BLKHL(X) series forced hot air circulation decorating lehr is designed for continuous secondary processing of glass bottles, containers, and similar products, including spray coloring and decal application.

In addition to firing glass products with silk-screen printing, spray coating or hand-applied decals, the BLKHL(X) series hot air circulation decoration furnace can also complete an annealing process to avoid internal forces caused

The BLKHL(X) series forced hot air circulation decorating lehr is designed for continuous secondary processing of glass bottles, containers, and similar products, including spray coloring and decal application

In addition to firing glass products with silk-screen printing, spray coating or hand-applied decals, the BLKHL(X) series hot air circulation decoration furnace can also complete an annealing process to avoid internal forces

The BLKHL(X) series forced hot air circulation decorating lehr is designed for continuous secondary processing of glass bottles, containers, and similar products, including spray coloring and decal application

The BLGH Series Heat-Resistant Glass Tempering Furnace is designed for continuous tempering of open-shaped glass products with uniform thickness and symmetrical geometry. Structurally, the furnace consists

Glass products are gradually heated to the optimal temperature in the heating zone before entering the tempering zone, where configured tempering fans rapidly and uniformly cool the products to achieve the desired tempering effect

Glass products are gradually heated to the optimal temperature in the heating zone before entering the tempering zone, where configured tempering fans rapidly and uniformly cool the products

The BLGH Series Heat-Resistant Glass Tempering Furnace is designed for continuous tempering of open-shaped glass products with uniform thickness and symmetrical geometry

Glass Tumbler Tempering Furnace

Жаропрочная печь для закалки стекла серии BLGH подходит для непрерывной закалки открытых стеклянных изделий однородной толщины и формы.

The mold cooling fan is a specialized high-pressure centrifugal fan designed for cooling molds in bottle-making machines and presses during glass product forming processes.

The mold cooling fan is a specialized high-pressure centrifugal fan designed for cooling molds in bottle-making machines and presses during glass product forming processes.

Mold cooling fans are designed using a new method for parameter optimization based on the diverse specifications and models of bottle making and press machines. They offer high overall pressure efficiency, a smooth performance curve, and significant energy savings.

Considering the wide variety of specifications and models of bottle-making machines and presses, this fan series employs a novel parameter optimization method in its design calculations.

They offer high overall pressure efficiency, a smooth performance curve, and significant energy savings.

It suitable for the continuous tempering production of glass products with open type, uniform thickness and symmetrical shape.

Electric heated glass decoration furnace

The product is used for continuous firing of glass bottles.

NUCLEAR (X) gas furnaces with hot air circulation are suitable for continuous firing of glass bottles.

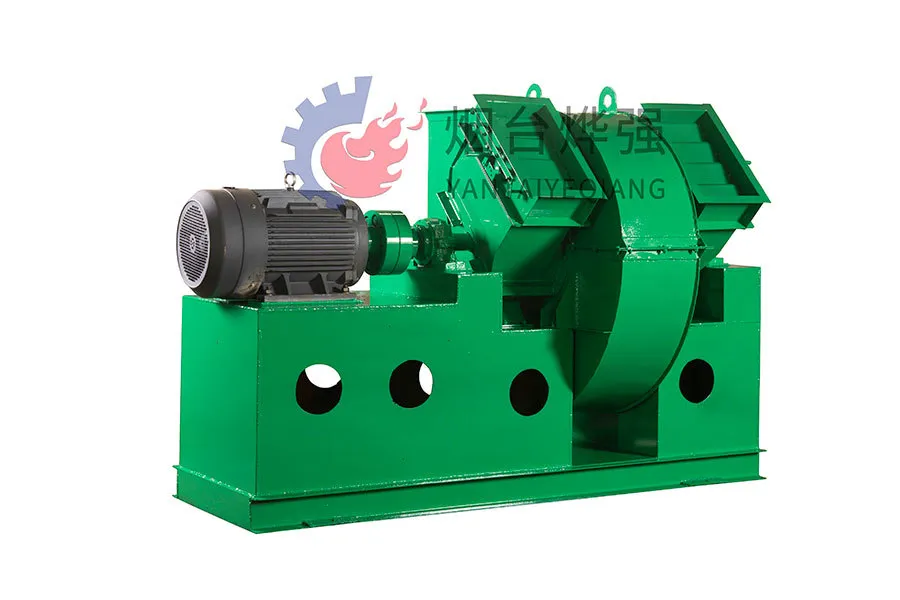

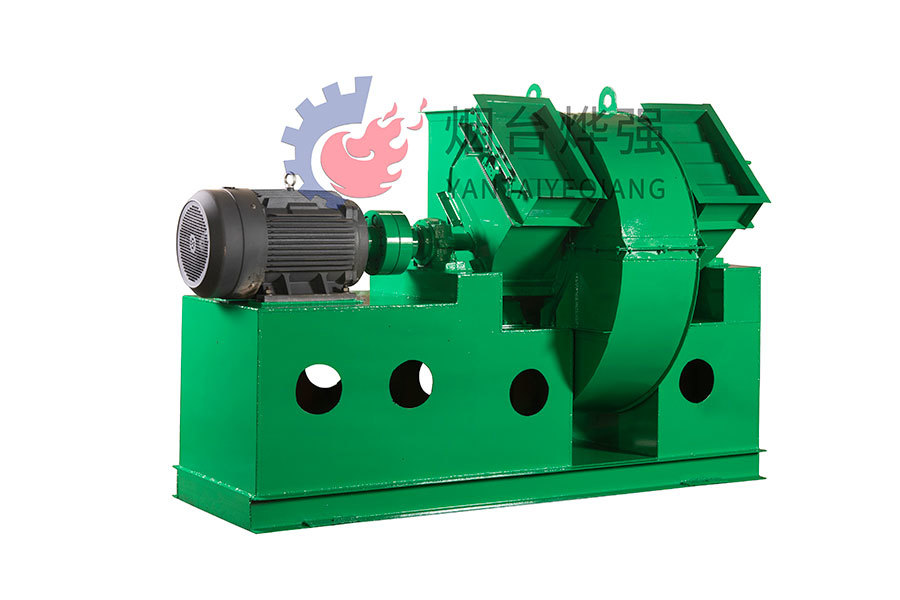

Its function is to break recycled glass bottles and larger cullet.

It is used to cool the molds of bottle machines and presses when forming glass products.

The mixers are necessary facilities in glass industry, used to mix compound glass materials homogeneous.