Related Products

Tempering furnace

It suitable for the continuous tempering production of glass products with open type, uniform thickness and symmetrical shape.

Category:

Keyword:

Tempering furnace

BLGH series heat-resistant glass product tempering furnaces are suitable for the continuous tempering production of glass products with open type, uniform thickness and symmetrical shape.Structurally, the equipment is roughly divided into three parts: heating zone, tempering zone, and quick-cooling zone.After the glass products are gradually heated to a suitable temperature through the heating zone, they directly enter the tempering zone, and the glass products are quickly and evenly cooled by the configured tempering fan, so as to achieve the effect of tempering the glass products.

According to the hot and cold state of the product, the furnace types of this series of tempering furnaces can be divided into online hot tempering furnaces and non-online cold tempering furnaces.According to the different transmission methods, this series of tempering furnaces can be divided into rotary tempering furnaces and mesh belt tempering furnaces.The mesh belt tempering furnace not only has the function of tempered glass products, but also can anneal glass products separately to eliminate internal stress, which has the effect of dual-use in one furnace.

This series of heat-resistant glass products tempering furnaces is an all-steel structure, assembled in segments, easy to transport, and can be quickly installed on the site of use.

This series of heat-resistant glass products tempering furnaces can realize automatic control of the temperature in the furnace, and the user can intuitively monitor the thermal parameters during the operation of the tempering furnace through the instrument or display screen.At the same time, the forced circulation of hot air can ensure the uniform effect of the temperature in the furnace, and improve the heat transfer efficiency, high efficiency and energy saving. It is currently the most advanced furnace type in the world. It is suitable for large glass production enterprises and glass production lines with a high degree of automation. Supporting use.

● Has more than 20 years of experience in glass equipment design and manufacturing

● Striving for perfection, quality casting with soul

● High quality, high efficiency, high precision

● Be proactive in timely, fast and energetic customer service to make it easier for them

A simple 3-step process for quick receipt of a commercial offer

Step 1: Leave your data, and within 24 hours our technicians will contact you.

Step 2: Confirm the drawings and select the materials for the production process and specifications.

Step 3: Get an offer and lead time.

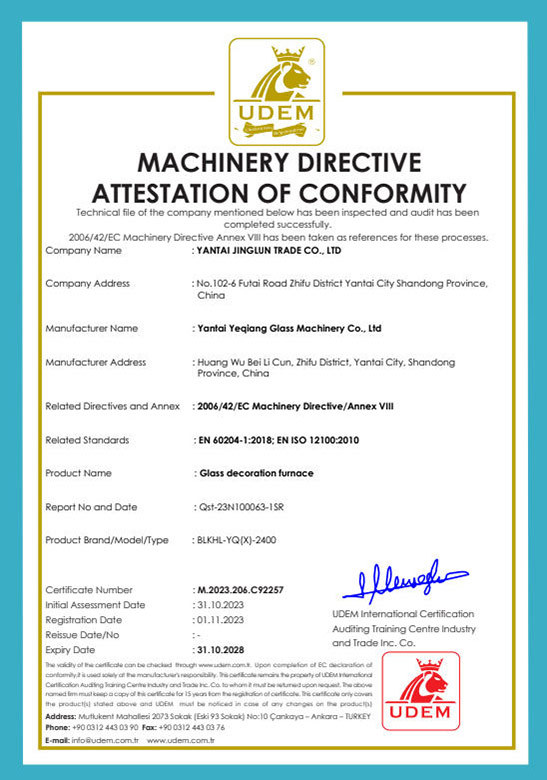

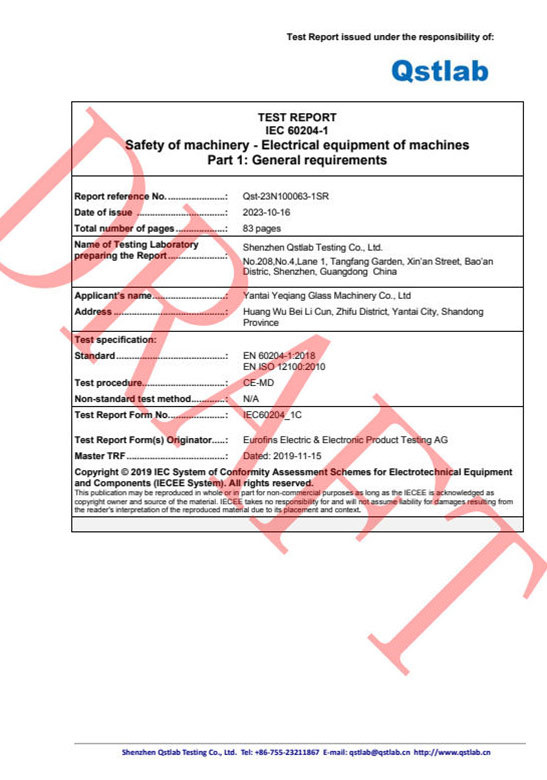

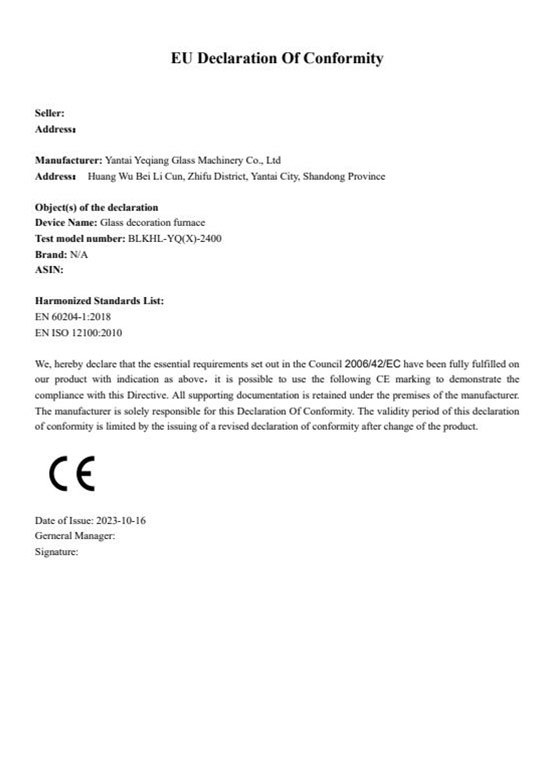

Certificates

Shipping and logistics

Exhibition Style